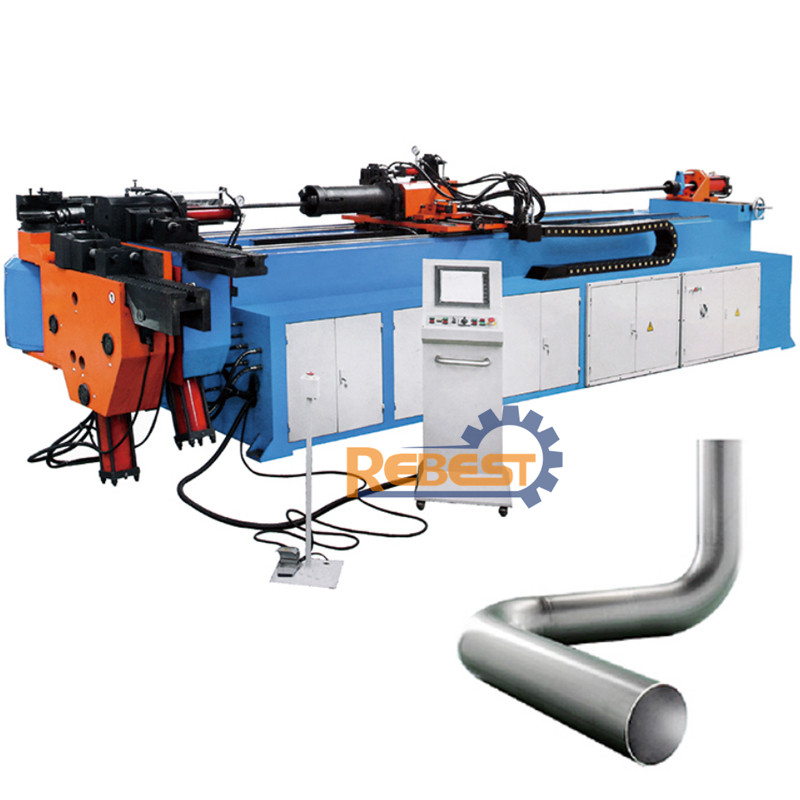

Pipe and Tube Bending Machines, commonly called tube and pipe bender, come in a lot of variety, including CNC tube bending machine, NC tube bending machine, automatic tube bending machine, semi-automatic pipe bending machine, hydraulic pipe bending machines, electric pipe and tube bender, and double head tube benders.

Predominantly, sheet metal bending machines work electromechanically. Thanks to the latest technological developments, these machines are capable of accelerating production and improving repeatability. At the same time, they are reducing the number of errors in production at every scale.

As one of the world's leading tube/pipe bending machine manufacturers, REBEST offers pipe and tube bending machines which are designed for both general and precision bending applications in a wide variety of industries, such as HVAC, aerospace, automotive, and furniture.

REBEST's sheet metal bending machines will save you money by providing maximum flexibility while offering the latest features and advanced technology. REBEST's tube and pipe bender can be used as stand-alone machines or building blocks to create a fully automated fabrication cell. All tube bending machines for sale can be coupled to autoloaders with weld-seam detectors and unloaders for lean operations.

REBEST is a known tube/pipe bending machine manufacturers, and all Sheet Metal Bending Machines have conducted the strictest quality inspection before delivery. Moreover, as one of the world's leading companies in the manufacture and development of tube and pipe bender, we offer you custom-made solutions for your individual tube bending machine.

The main parts of Pipe and Tube Bending Machines

● Bend Die

The bend die, also known as the bend form or the radius die, is the most important part of a rotary-draw bending machine. The tube clamps to the bend die and the drawing process produce the necessary bend. The selection of die is very important, as the tube’s inside radius depends on it.

● Clamp Die

The clamp die presses the tube onto the bend die. Its main purpose is to prevent the pipe from slipping.

● Pressure Die

The pressure die makes sure the tube follows the bend die’s contour.

● Wiper Die

A wiper die places just after the bend die. The purpose is to avoid the formation of any humps on the inside radius. During the forming process, the material turns plastic during bending. It may result in wrinkles with large deformations. Thus, adding a wiper die just after the bend die helps to smooth the surface.

● Mandrel

In bending steel and aluminum tubes, a mandrel is necessary for more difficult jobs. Bending a small radius, thin tubes or harder materials can result in an unsatisfactory outcome. In those cases, a mandrel can be handy. The mandrel’s objective is keeping the tube from collapsing.

The Advantages of Pipe and Tube Bending Machines

● Consistent tube bends with no deformities

Pipes and tubes can be fabricated into a very small radius without producing crinkles or distortions using a specific technique. This technique using a pipe and tube bending machines for sale can save time and money while reducing any possible defects.

● Maintaining tube bending sturdiness

A major advantage of sheet metal bending machines is their ability to maintain the overall sturdiness and solidity of tubes and pipes despite the bends. This is important because these pipes and tubes are used in a vast number of applications from playground equipment and exhaust machines to traffic signposts.

● A large number of pipe bending designs

Pipe bending can be designed for a variety of requirements based on what a client may need. Pipe and tube bending machines are capable of specialized metal bending that can cater to any requirements a client may have.

● Variety of applications

Specialized pipes are used in a vast number of applications that are required in industrial and domestic environments. A pipe and tube bender is extremely versatile and can be relied on for a wide range of usage.

The Applications of Pipe and Tube Bending Machines

REBEST was established in 1987 as a specialized tube/pipe bender manufacturer of a wide variety of tube/pipe benders and tube bending machines, such as CNC tube bending machine (pc servo or plc control), NC tube bending machine and specially customized pipe benders.

Our range of pipe and tube bending machines comprises machines and systems for a variety of application areas. Dedicated to providing customers with the most credible and reliable industrial equipment, the company has been making relentless efforts on superior technology and engineering to enhance the performance of the pipe and tube bender in different application such as Automotive Components, Furniture Industry, Shipbuilding Industry, Aviation Parts, Public Transportation, Fitness Utilities, Medicare Parts, HVAC system, Pipe Fitting, etc.

The Comparison of CNC automatic pipe bending machine and semi-automatic pipe bending machine

CNC automatic pipe bending machine

CNC automatic pipe bending machine bends tubes with the greatest productivity, dynamics, and precision. Tube feeding and tube turning are executed with servo-electric control. Bending drive and clamping functions operate hydraulically. The hybrid concept unites the advantages of electrical and hydraulic drive technology. Bending programs can be created, processed and administrated directly on the machine. Fully automatic CNC-controlled tube bending machines are the first choice when the maximum in precision and productivity are required.

●Characteristics

The maximum in dynamics, precision, and productivity due to servo-electrically controlled axes

Leading-edge CNC-S control technology with innovative machine software

●Applications

Metal construction, metalwork, and general machine construction, pipework construction, hydraulics, plant construction